Services - Preventive Maintenance Of Diesel Generator Set

At NDSS-Network Diesel Sales & Service, we understand the importance of keeping your diesel generator set in top condition. That's why we offer comprehensive preventive maintenance services to ensure your generator is always running at peak performance.

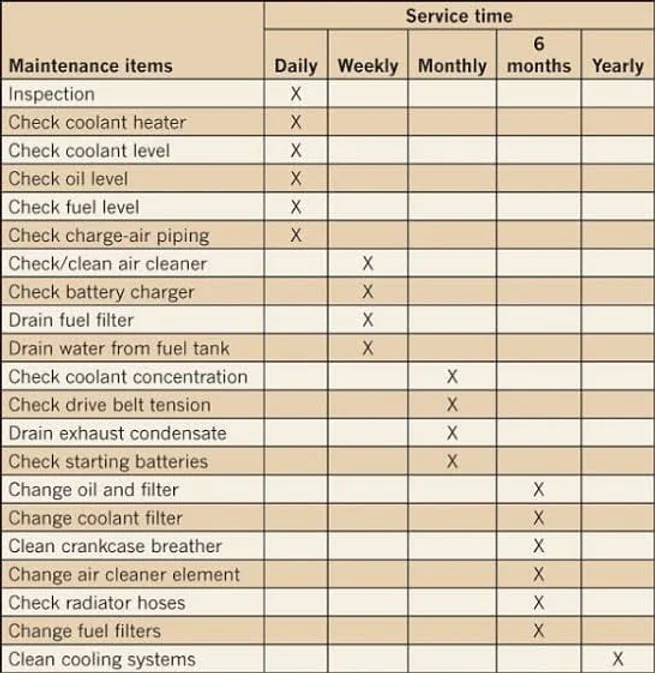

Preventive maintenance for diesel generator sets is essential to ensure their durability and smooth operation. Our team of expert technicians provides a wide range of preventive services, including fuel system checks, battery maintenance, oil changes, and more. We use only high-quality parts and components to maintain your generator set, ensuring that it meets or exceeds the manufacturer's specifications.